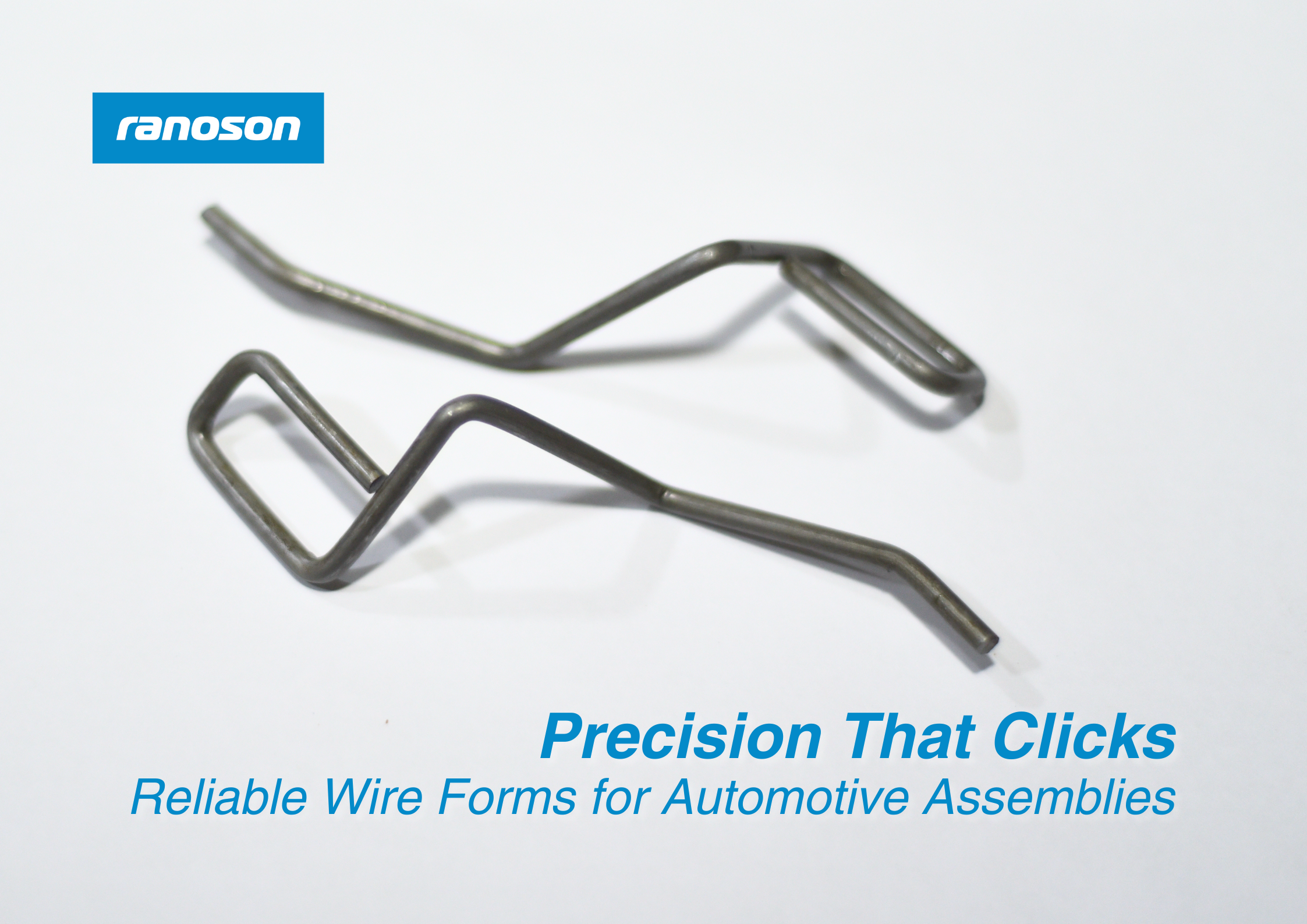

Precision That Clicks: How Ranoson Solved a Challenge for a Leading Tier 1 Supplier

Posted on: 31 Oct, 2025

Every assembly line depends on one thing above all, consistency. When one small part doesn’t perform as expected, the entire system feels it. That’s exactly what was happening with one of our Tier 1 automotive customers. They were struggling with inconsistent locking action in a key assembly supplied to an automotive giant. The problem wasn’t the design itself but how the part was being made.

The Challenge

Before coming to us, the supplier was getting these wire forms made manually using basic tools. On the surface, it seemed like a simple process, but it came with a long list of issues. The forming was inconsistent, the cutting left burrs at the edges, and the parts often came out deformed. Every batch looked a little different from the previous one. Some worked perfectly, others didn’t fit as smoothly, and that variation was showing up in the assembly’s performance.

On top of that, manual forming meant the production rate was slow and unpredictable. Deliveries often got delayed, which made it harder for the Tier 1 supplier to meet their own timelines. Quality checks had to be done frequently, and even then, rejection rates were high. What this really meant was that the supplier couldn’t rely on a steady, repeatable process, and that’s a big problem in automotive manufacturing where precision is everything.

When They Came to Ranoson

When the supplier approached us, they were clear about one thing: they needed precision. The drawings they shared had specific dimensional requirements and tight tolerances. Even a small deviation could affect the locking consistency in the final assembly. We knew the solution would come down to one key factor, eliminating manual error and introducing controlled, automated forming.

Our team began by studying their existing process and understanding where the variations were happening. The biggest cause was uneven bending angles and cutting inaccuracies from hand tools. These inconsistencies were creating minor deformations that affected both fit and function. To solve this, we first moved the entire forming process to a CNC-based setup.

Our Approach

We used a precision multi-axis CNC wire forming machine to manufacture the parts exactly as per the drawing provided. Every bend, curve, and cut was programmed to maintain dimensional accuracy within the specified tolerance range. By automating the process, we removed all the variability that comes from manual forming.

But making the parts wasn’t enough. We wanted to ensure that every piece delivered matched the same quality standards. As our standard operation procedure, each batch was checked for dimensional accuracy, burr-free edges, and overall consistency.

The automation didn’t just improve precision. It also brought reliability to the entire supply chain. With consistent output and stable production rates, we could deliver on time, every time. The Tier 1 supplier no longer had to worry about production delays or rejected batches. For them, that meant fewer line stoppages, smoother assembly, and a much more predictable workflow.

The Result

The difference was immediate and measurable. The locking action in the automotive assembly became consistent. Every wire form fit and functioned exactly as intended. The edges were clean, the dimensions were precise, and the deformation issues were completely eliminated. Rejection rates dropped to zero. What started as a small trial order quickly turned into a regular, long-term supply relationship.

We didn’t just solve a manufacturing problem, we restored confidence. For a Tier 1 supplier serving an automotive giant, that reliability makes all the difference. It ensures that their own commitments are met without compromise. That’s the kind of precision and dependability we aim to deliver with every order, no matter how small the part may seem.

Wire forms may look simple, but they’re often the unsung heroes of an automotive assembly. Their performance depends entirely on how accurately they’re made. A small bend angle off by a few degrees or an edge left unfinished can change how the entire assembly behaves. That’s why precision manufacturing and strict process control matter and that’s exactly what we focus on at Ranoson.

This case is a good reminder that automation isn’t just about speed or volume. It’s about bringing repeatability and control into every part of the process. When the right machine, material, and method come together, even the smallest component can play a big role in the reliability of the whole system.

Looking Ahead

Since then, we’ve continued to support this Tier 1 supplier with consistent supplies of precision wire forms. Their production lines run smoother, their inspection time is lower, and their confidence in our parts has only grown stronger. We take that as a sign that our approach, combining advanced technology with strict quality discipline, is working exactly as it should.

For us, every success story like this reinforces one belief: precision is not optional. It’s what makes the entire system click together.

Need reliable wire forms for your automotive assemblies?

Let’s build precision together.

📧 sales@ranoson.co.in

📞 +91 7895010088 | +91 7217013190