Top 5 Challenges in Spring Manufacturing and How to Overcome Them

Posted on: 28 Oct, 2025

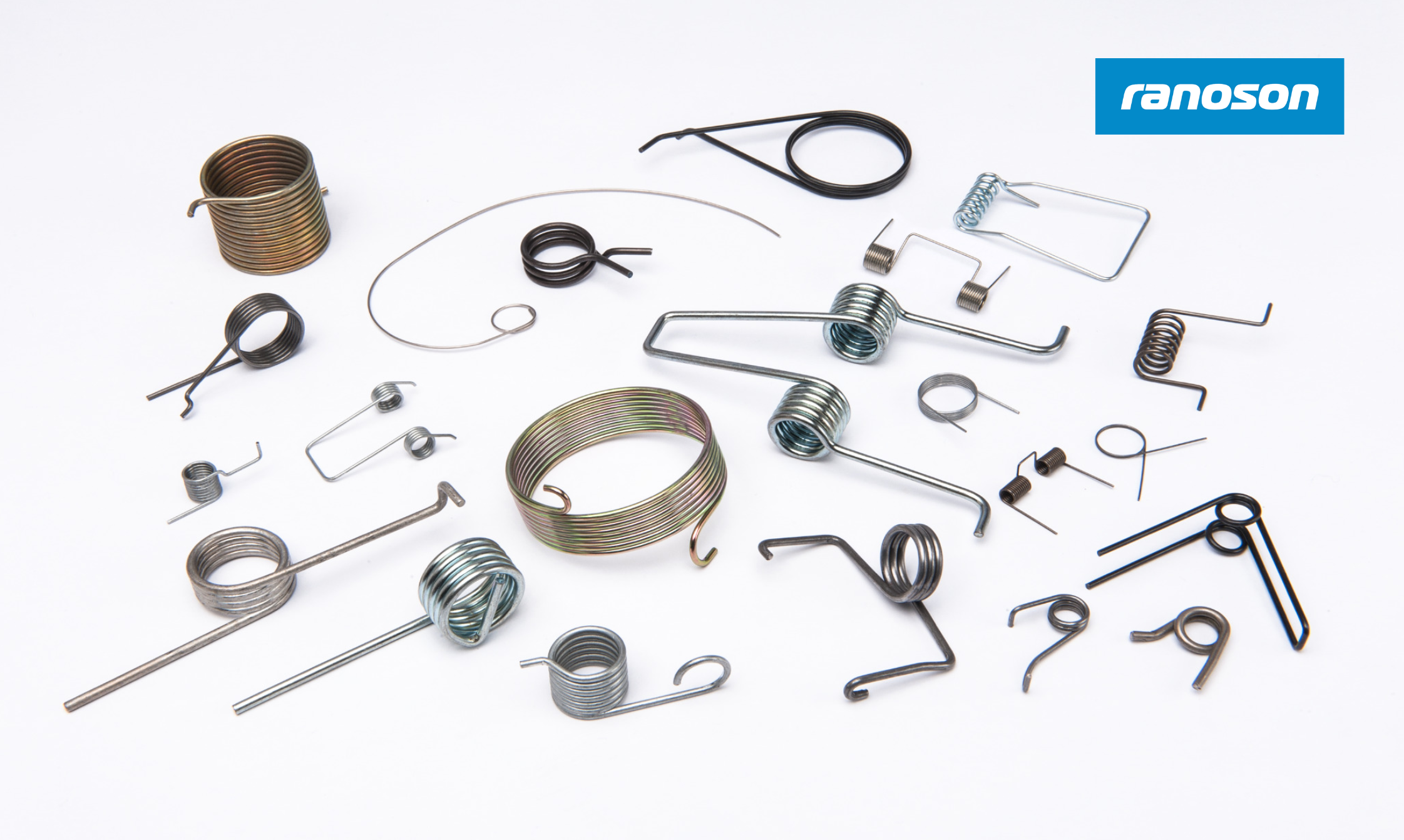

Spring manufacturing might look straightforward from the outside. A coiled wire, some tension, and a few machines. But anyone who’s actually been on the production floor knows that making a spring that performs reliably over millions of cycles is far from simple. It’s a process that blends material science, design precision, and deep technical understanding. Let’s look at five of the most common challenges in spring manufacturing and what it takes to solve them.

1. Maintaining Dimensional Accuracy

Springs are small components, but they often carry big responsibilities. A fraction of a millimeter in diameter or pitch variation can completely alter how a spring behaves under load. Maintaining dimensional accuracy becomes especially complex in high-volume production where even tool wear or wire inconsistencies can throw off results.

The Solution: Consistency starts with precision equipment. CNC and multi-axis spring coiling machines allow continuous monitoring and control of every coil. Regular calibration, automated feedback systems, and skilled operators together ensure that every spring meets tolerance requirements. Investing in metrology tools like digital gauges and optical inspection systems also helps verify output accuracy without slowing production.

2. Managing Material Quality and Variability

The performance of a spring depends directly on the quality of its raw material. Even small differences in tensile strength, surface finish, or wire diameter can affect the spring’s load-bearing capacity and fatigue life. Sourcing consistent material and handling it correctly during manufacturing are ongoing challenges.

The Solution: Build strong relationships with verified wire suppliers who can provide certification and traceability for every batch. Once the material arrives, proper storage and handling are crucial to avoid rust or contamination. During production, automated tension controls and temperature monitoring prevent internal stress that can weaken the wire structure.

3. Controlling Residual Stresses

When a spring is coiled, internal stresses build up in the wire due to bending and twisting. If left untreated, these stresses can cause deformation, load loss, or even early failure during operation. This issue is especially critical in springs used for high-load or high-temperature applications.

The Solution: Stress-relieving is key. It’s a controlled heat treatment process that restores the wire’s internal balance after coiling. The spring is heated to a moderate temperature, usually between 200°C and 450°C depending on the material, and then cooled in a controlled manner. This step enhances stability and fatigue life. While not every spring requires stress-relieving, it’s essential for those expected to perform under demanding or repetitive conditions.

4. Ensuring Surface Quality and Corrosion Resistance

Springs operate in diverse environments — from the humid air of coastal areas to the high heat inside engines. Surface defects like scratches, pits, or uneven coatings can quickly lead to fatigue failure or corrosion. Maintaining clean surfaces and applying the right protective treatment is one of the biggest practical challenges manufacturers face.

The Solution: Start with clean, lubricated wire. Use die and tooling materials that reduce surface friction during coiling. After production, choose the right finishing process based on the spring’s use case — shot peening to improve fatigue life, electroplating or powder coating for corrosion protection, and polishing for aesthetic or precision applications. Regular inspection after coating ensures that the finish hasn’t altered the spring dimensions.

5. Balancing Customization with Production Efficiency

Different industries require different spring properties — from ultra-soft compression springs in electrical devices to heavy-duty torsion springs in machinery. Customization is often a must, but every change in design or load parameter can slow down production, especially if setups are manual or require tooling changes.

The Solution: Automation and flexibility go hand in hand. CNC coiling technology, digital design validation, and in-house toolmaking allow manufacturers to switch quickly between designs without losing precision or time. A data-driven approach also helps track which parameters deliver the best results for specific clients, turning customization into a repeatable, efficient process rather than a production bottleneck.

What This Means for OEMs and Sourcing Managers

When sourcing springs and wire forms, it’s worth looking beyond price and lead time. Ask how the manufacturer handles these five challenges. A supplier that invests in precision equipment, quality control, and heat treatment expertise is more likely to deliver consistent, durable products. It also means fewer replacements, fewer line disruptions, and more reliability in your end product.

How Ranoson Tackles These Challenges

At Ranoson, precision isn’t an afterthought, it’s the foundation. Our advanced CNC and multi-axis machines are designed for consistency and scale. Every spring we produce goes through strict dimensional, material, and performance checks. We apply the right stress-relief process depending on the application, ensuring each spring performs exactly as intended. By combining technical know-how with in-house process innovation, we deliver springs that don’t just meet specifications but exceed expectations in real-world performance.

Spring manufacturing will always involve challenges, but with the right mix of technology, discipline, and expertise, those challenges turn into opportunities to improve. And that’s where we focus. Not just on producing springs, but on building long-term reliability into every coil we make.

📧 sales@ranoson.co.in

📞 +91 7895010088 | +91 7217013190