How High-Precision Springs Drive Automotive Performance

Posted on: 23 Sep, 2025

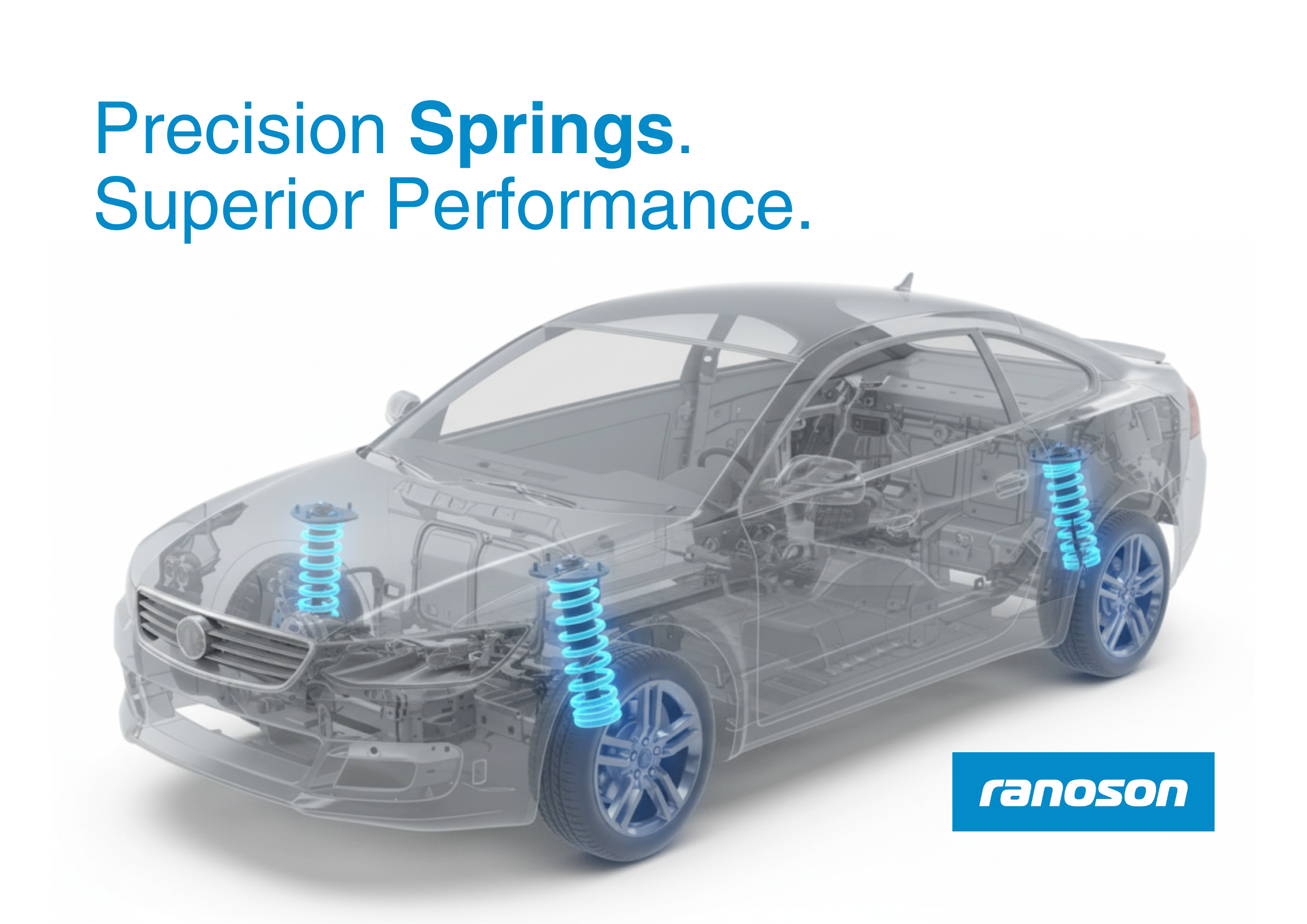

Every vehicle depends on thousands of components working in harmony. Among them, springs might look simple, but they carry enormous responsibility. From suspensions and brakes to seats and door locks, precision springs make the difference between a car that just runs and one that delivers safety, comfort, and long-term reliability.

Why Precision Matters in Automotive Springs

Automotive environments are tough. High heat, constant vibrations, sudden shocks, and daily wear test every component. Springs that lack precision can lose their tension, deform, or even fail under load. When that happens, it’s not just performance that suffers but also safety.

High-precision springs are designed and manufactured with strict tolerances. That means they perform consistently, cycle after cycle, without compromising strength or flexibility. For OEMs and Tier 1 suppliers, this reliability translates directly into fewer failures in the field, lower warranty claims, and greater trust from end users.

Key Areas Where Springs Impact Vehicle Performance

- Suspension Systems: Springs absorb shocks from uneven roads, keeping rides smooth and stable. Precision ensures the suspension behaves predictably, enhancing both comfort and safety.

- Braking Mechanisms: Brake systems use springs to reset components after engagement. Any inconsistency here affects stopping distance and vehicle safety.

- Seats and Interiors: Springs in seats, armrests, and mechanisms provide comfort and usability over years of use. Without durability, these features wear out too quickly.

- Door Locks and Handles: Even small springs in latches and locks play a role in vehicle reliability and user satisfaction.

- Engine and Transmission Components: Specialized springs regulate valves, clutches, and other systems. Precision directly influences performance and fuel efficiency.

Durability is Non-Negotiable

Vehicles are expected to last for years, often across tough terrains and climates. That means springs must be made from carefully chosen materials and undergo processes like heat treatment and stress testing to guarantee performance. Precision engineering ensures that every spring resists fatigue, maintains elasticity, and meets international quality standards.

What This Means for Automotive OEMs and Suppliers

When you choose a supplier, you’re not just buying a component. You’re buying reliability, efficiency, and long-term value. High-precision springs ensure vehicles meet performance expectations, pass quality checks, and keep customers satisfied on the road. With Ranoson, you also get the assurance of springs that are engineered with durability and performance as the top priorities.

Automotive performance depends on precision down to the smallest part. Springs may be hidden inside assemblies, but their role is visible in every safe stop, smooth ride, and reliable start. Partnering with a manufacturer that combines advanced spring design, proven durability, and precision engineering means you stay ahead of both competition and customer expectations.

Let us help you accelerate your growth with high-precision springs designed for performance and built for durability.

📧 sales@ranoson.co.in

📞 +91 7895010088 | +91 7217013190