A Beginner’s Guide to Spring Load Testing

Posted on: 21 Aug, 2025

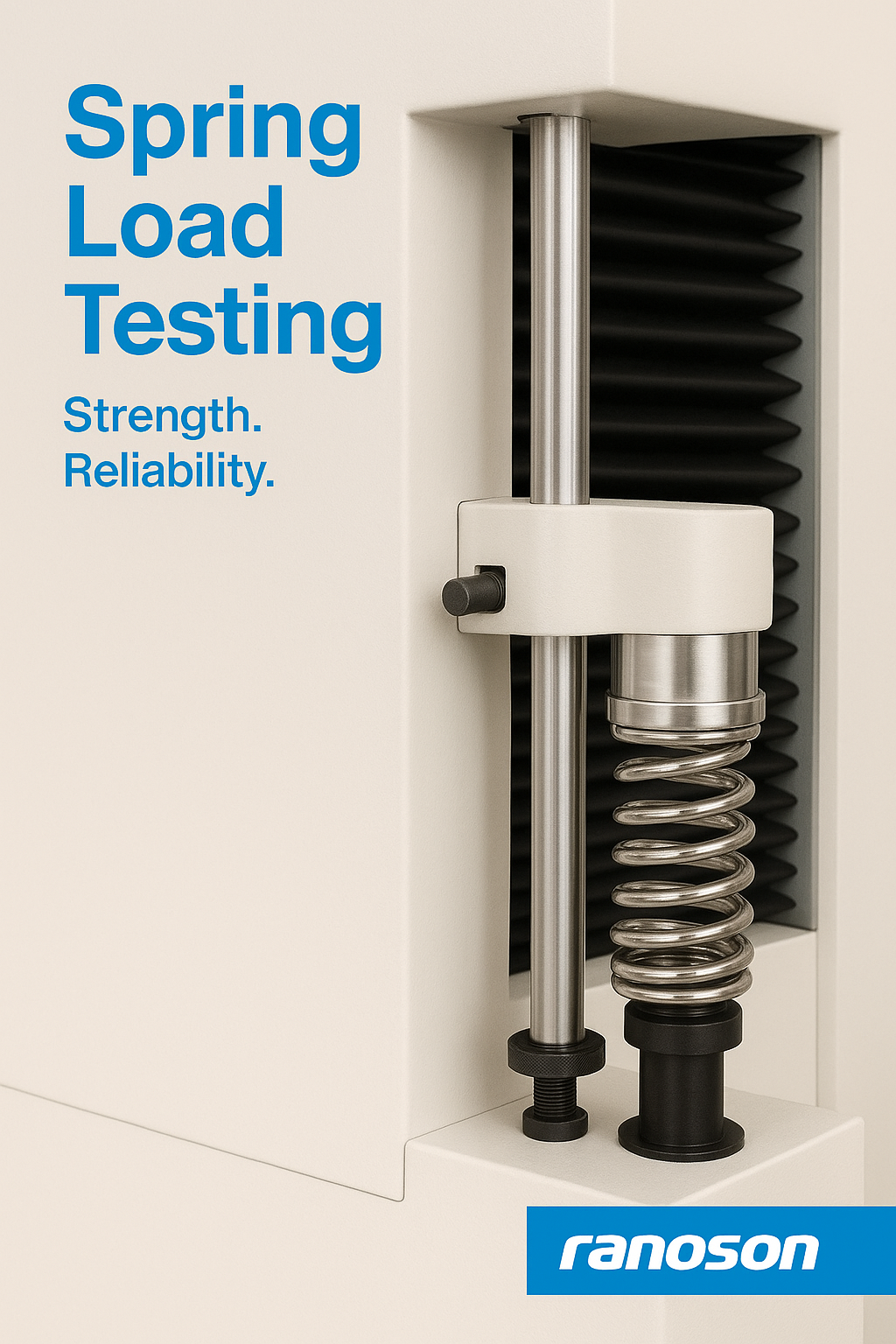

When you rely on springs for performance in your product, guessing is not an option. That is where spring load testing comes in. It gives you hard data on how a spring behaves under force and whether it meets the requirements your industry demands. Let’s break down the process so you know exactly how it works and why it matters.

What is Spring Load Testing?

Spring load testing is the process of applying force to a spring and measuring how it responds. The purpose is simple: confirm that the spring performs as expected before it goes into an assembly. This test is not just about quality control, it’s about preventing costly failures in the field.

Why It Matters

Springs might look small, but their role is big. In an automotive brake, a thermostat, or even a circuit breaker, one weak spring can disrupt the entire system. Load testing ensures that every spring meets the performance, safety, and reliability standards that industries count on.

Step-by-Step Process of Spring Load Testing

1. Define the Requirements

Before any testing begins, you need clear specifications. What is the load capacity? What is the deflection range? What tolerance is acceptable? Setting these benchmarks ensures you are not just testing, you are testing against meaningful criteria.

2. Prepare the Spring

The spring must be inspected and cleaned before testing. Any surface defects or residual dirt can influence the accuracy of the results. This step ensures that you are testing the spring itself, not the conditions around it.

3. Choose the Right Testing Equipment

Load testing machines come in different configurations, from manual test stands to automated systems with digital readouts. The choice depends on the precision level required. For industrial standards, accuracy is non-negotiable.

4. Apply Load

The spring is placed in the machine and force is applied gradually. The goal is to measure how the spring compresses or extends at specific loads. This is where the spring’s behavior under stress becomes visible.

5. Record the Data

Measurements are taken at defined load intervals. This data creates a load-deflection curve, which is the blueprint of the spring’s performance. Any deviation from expected values is a red flag that the spring may not perform reliably in application.

6. Compare Against Standards

Industries follow established standards such as ASTM, ISO, or customer-specific requirements. The recorded data is compared against these benchmarks. Passing the test confirms that the spring is fit for purpose. Failing the test means the spring goes back to review and redesign.

Key Benefits of Load Testing

- Material efficiency – Ensures you are not overdesigning or underdesigning the spring, saving cost and material.

- Performance testing – Confirms that the spring behaves exactly as required under operating conditions.

- Integration – Makes sure the spring will function smoothly within the assembly or system.

- Longevity – Identifies whether the spring can handle repeated use without loss of performance.

What This Means for Your Business

When load testing is part of your quality process, you reduce risks, improve product reliability, and strengthen customer trust. It is not just a test, it is an investment in your reputation.

Spring load testing may sound technical, but at its core, it is about peace of mind. You know the spring you put in your product will do its job, every time. If you are working with a partner who takes this process seriously, you are already one step ahead in building reliable products.

Let Us Help You Accelerate Your Growth

If you want springs that are tested, reliable, and designed for your industry, we are here to support you. Talk to our team and see how precision testing can add value to your products.

📧 sales@ranoson.co.in

📞 +91 7895010088 | +91 7217013190

🌐 www.ranoson.co.in