How Wire Forms Are Revolutionizing the Electronics Industry

Posted on: 05 Aug, 2025

Walk into any modern electronic device, and chances are, wire forms are quietly doing their job in the background: connecting, grounding, supporting, and holding things together. These small components might not get the spotlight, but they’re changing the game in electronics design and manufacturing.

What Are Wire Forms?

Wire forms are custom-shaped wires bent to perform specific functions. Unlike springs, which store energy, wire forms act as structural or functional elements: think of clips, brackets, contact arms, guides, or antennae. Their flexibility, precision, and versatility make them critical in everything from tiny sensors to large industrial electronics.

Why They're a Big Deal in Electronics

Here’s the thing: electronics are getting smaller, smarter, and faster. But none of that works without internal components that can keep up. Wire forms solve multiple challenges for OEMs:

- Compact Design: Custom shapes allow wire forms to fit into tight spaces without sacrificing performance.

- Durability: With the right material and coating, wire forms can withstand high temperatures, vibration, and wear. Ideal for automotive and industrial electronics.

- Conductivity: Many wire forms double as electrical contacts, ensuring smooth flow of current.

- Cost Efficiency: Once the tooling is done, wire forms can be mass-produced with high consistency.

Precision Engineering Behind the Scenes

OEMs and Tier 1 suppliers in electronics are leaning heavily on high-precision manufacturing partners to develop wire forms that meet exact tolerances. That’s where CNC wire forming comes in. It allows for tight tolerances and repeatabilit. Exactly what sensitive electronic systems need.

Applications That Might Surprise You

Wire forms are found in a wide range of electronic products:

- LED Lighting: Mounting brackets and electrical connectors

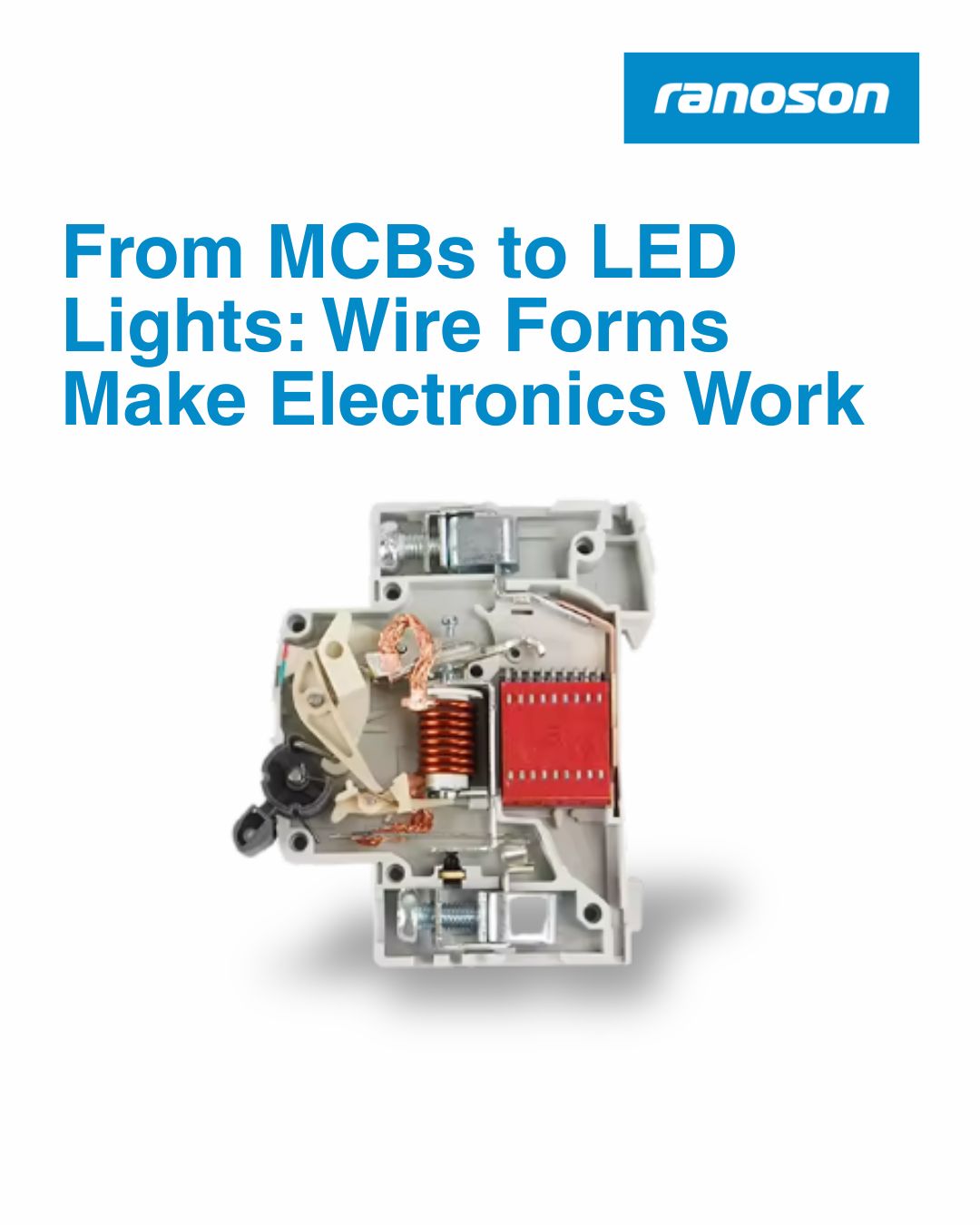

- MCBs and Switchgear: Contact arms and spring mechanisms

- Refrigerators and Washing Machines: Sensor clips and actuator links

- Automotive Electronics: Battery terminals, signal routing guides, grounding springs

- Mobile Devices: Antenna components and internal clips

All these components require high precision, corrosion resistance, and fatigue strength. Three things wire forms are built for.

What This Means for Sourcing Managers

If you're sourcing electronic components, the right wire form supplier can make or break your product’s performance. Here's what to look for:

- Material expertise

- Capability for close tolerances and high-volume runs

- In-house tool design and prototyping

- Testing for fatigue, conductivity, and corrosion resistance

At Ranoson, we help OEMs develop custom wire forms that don’t just meet the brief, but they improve product lifespan, reduce failure rates, and simplify assembly.

Wire forms may not be the most glamorous part of electronics manufacturing, but they’re essential to keeping today’s devices compact, reliable, and efficient. If you’re not already thinking about how they can improve your product design, you should be.

Let us help you accelerate your growth with springs that last.

📧 sales@ranoson.co.in

📞 +91 7895010088 | +91 7217013190

🌐 www.ranoson.co.in