How Heat Treatment Improves Spring Performance & Durability

Posted on: 21 Jun, 2025

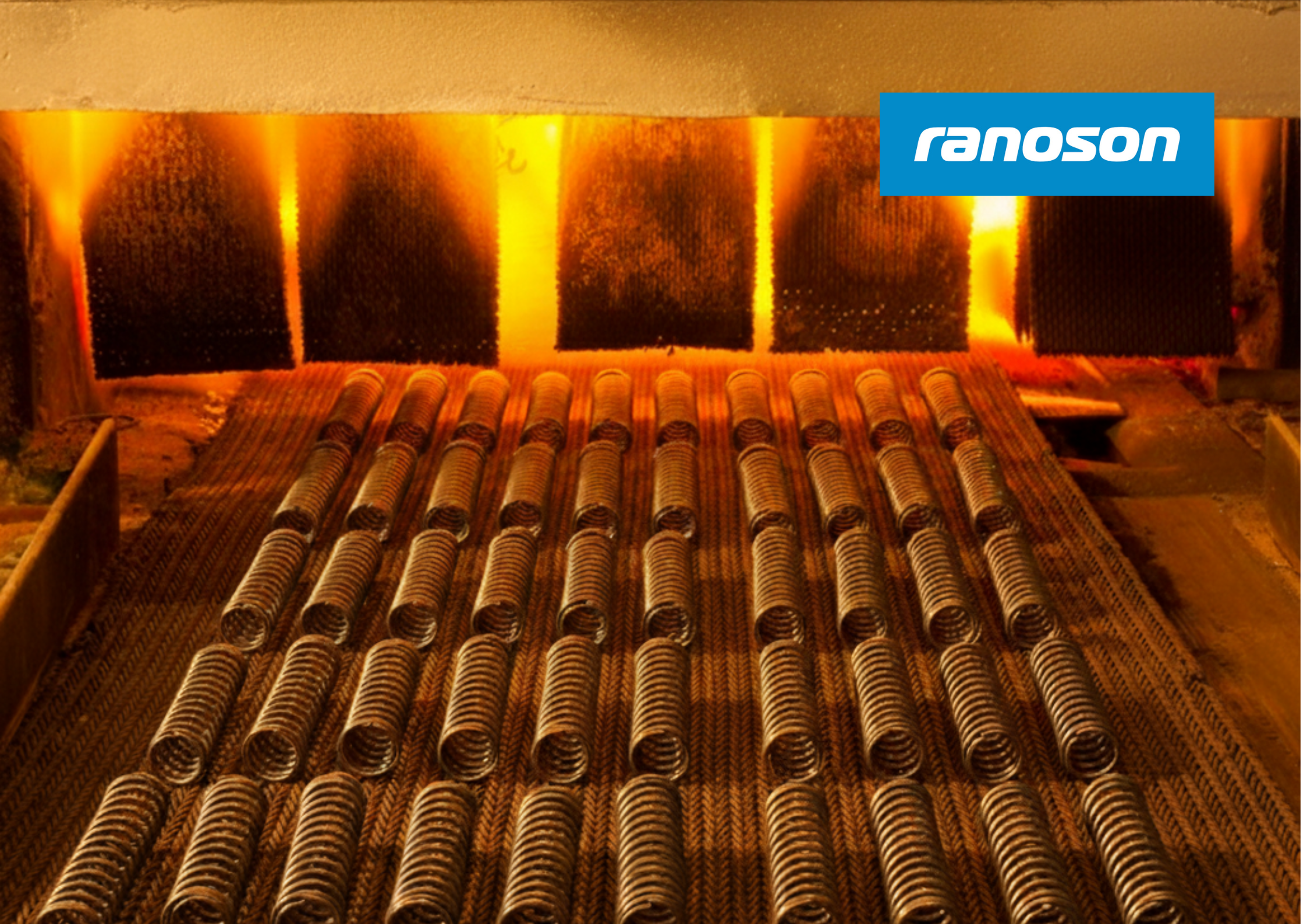

When it comes to manufacturing high-performance springs for industrial applications, the material and design are only part of the story. One of the most critical—and often overlooked—factors that determine a spring’s reliability is heat treatment.

At Ranoson, an ISO 9001:2015 certified custom spring manufacturer, we use advanced heat treatment techniques to ensure that every spring performs as expected in demanding industrial environments. Let’s explore why heat treatment matters and how it can make or break your spring’s performance.

Why Heat Treatment Matters in Spring Manufacturing

Springs are designed to absorb and release energy repeatedly. Without proper heat treatment, springs are prone to:

- Premature fatigue

- Permanent deformation

- Breakage under load

Heat treatment improves the internal structure of the spring material, making it stronger, tougher, and more fatigue-resistant. The process aligns the metal’s grain structure and relieves internal stresses that develop during coiling and shaping.

Types of Heat Treatment Used for Springs

1️⃣ Stress Relieving

- Performed immediately after forming.

- Removes residual stresses caused by bending and shaping.

- Reduces the risk of cracks and ensures dimensional stability.

2️⃣ Hardening and Tempering

- Hardening: Heating the spring material to a high temperature and rapidly cooling it (quenching).

- Tempering: Reheating to a moderate temperature to reduce brittleness while maintaining strength.

- Essential for springs that need to withstand heavy cyclic loads.

3️⃣ Annealing

- Used on certain specialty alloys.

- Softens the material before or after forming to improve machinability and ductility.

Impact of Heat Treatment on Spring Performance

✔ Increased Fatigue Life: Springs can withstand more cycles without failure.

✔ Higher Load Capacity: Heat-treated springs can bear more force without deformation.

✔ Improved Dimensional Stability: Minimizes changes in size or shape during use.

✔ Enhanced Corrosion Resistance: Especially when paired with surface treatments.

Why Choose Ranoson for Heat-Treated Springs?

As a trusted custom spring manufacturer in India, Ranoson brings expertise, technology, and rigorous quality control to every spring we produce. Our heat treatment processes are designed around your application’s requirements.

✔ Controlled Temperature Processes monitored with advanced equipment

✔ Batch-wise Quality Checks for hardness, microstructure, and tensile strength

✔ Integration with CNC Coiling & Precision Testing to ensure uniform results

✔ Tailored Solutions for high-stress or high-temperature applications

Real-World Applications of Heat-Treated Springs

✔ Automotive suspension springs require hardening and tempering for durability on rough roads.

✔ Electrical equipment springs need stress relieving to maintain precise operation.

✔ Heavy machinery demands springs that can endure heavy cyclic loads with minimal fatigue.

Let’s Build the Future—Together

Spring failure doesn’t just cost money—it costs trust. With expertly heat-treated springs from Ranoson, you’re investing in products designed for endurance, precision, and long-term success.

Let us help you accelerate your growth with springs that last.

📧 sales@ranoson.co.in

📞 +91 7895010088 | +91 7217013190

🌐 www.ranoson.co.in